Author:Kangdi 21-06-2024

In an era where environmental consciousness is paramount, the healthcare industry is increasingly focusing on sustainable practices. At the forefront of this green revolution are capsicum plasters, a popular pain relief solution now being manufactured with both efficacy and eco-friendliness in mind. This article explores the innovative approaches being taken to ensure these products deliver on both fronts.

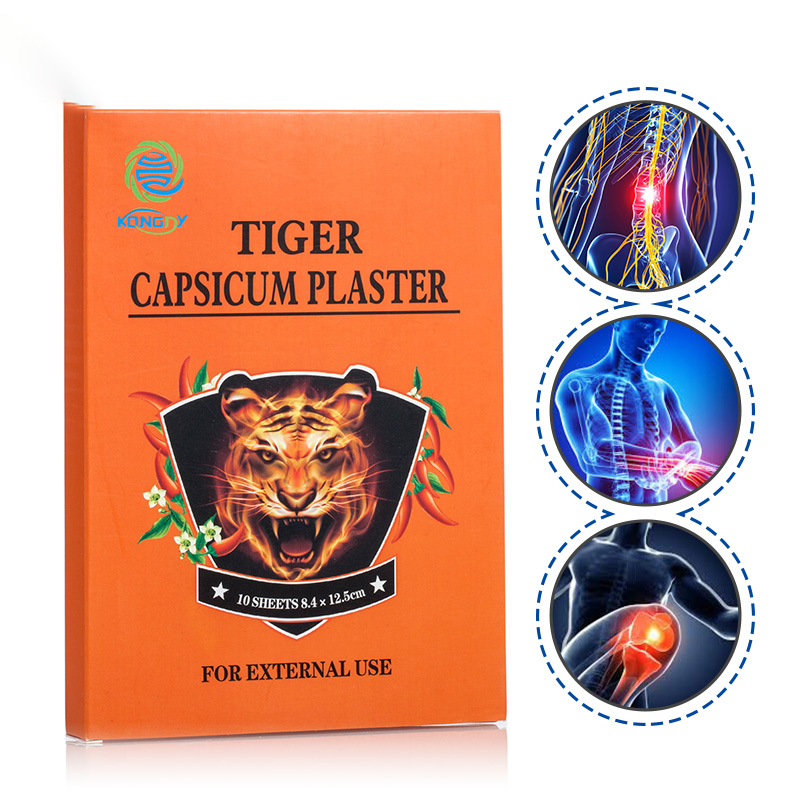

01. The Power of Capsicum Plasters

Capsicum plasters, derived from chili peppers, have long been valued for their ability to provide localized pain relief. The active compound, capsaicin, works by temporarily desensitizing nerve receptors, offering relief from various musculoskeletal pains.

02. The Challenge: Balancing Effectiveness and Sustainability

Traditionally, the production of capsicum plasters has involved processes and materials that weren't always environmentally friendly. The challenge has been to maintain the product's effectiveness while reducing its ecological footprint.

03. Eco-Friendly Innovations in Capsicum Plaster Manufacturing

1. Sustainable Sourcing of Capsicum

Partnering with organic capsicum farms

Implementing fair trade practices

Reducing transportation emissions through local sourcing

2. Green Extraction Methods

Utilizing supercritical CO2 extraction to minimize solvent use

Implementing closed-loop systems to reduce waste

Employing energy-efficient extraction equipment

3. Biodegradable Backing Materials

Replacing synthetic backings with plant-based alternatives

Developing compostable adhesives

Ensuring the breakdown of materials doesn't release harmful substances

04. Consumer Response and Market Trends

The shift towards green manufacturing has been met with enthusiasm from environmentally conscious consumers. Market trends indicate a growing preference for eco-friendly pain relief solutions, with many willing to pay a premium for sustainable products.

05. Future Directions in Eco-Friendly Capsicum Plaster Production

As technology advances, we can expect further innovations in green manufacturing:

Development of fully biodegradable plasters

Integration of smart technology for optimized application and disposal

Expansion of zero-waste manufacturing facilities

Exploration of new, sustainable capsaicin sources

06. Conclusion: A Step Towards a Greener Future

The green manufacturing of capsicum plasters represents a significant step towards sustainability in healthcare products. By balancing effectiveness with eco-friendliness, manufacturers are not only providing relief to those in pain but also contributing to the health of our planet. As consumers, choosing these environmentally responsible options supports a future where our well-being and that of the Earth go hand in hand.

This commitment to green manufacturing in the production of capsicum plasters sets a precedent for other healthcare products, paving the way for a more sustainable and responsible industry overall.

0086 19937104978

0086 19937104978