Author:Kangdi 23-08-2024

In the heart of the wellness industry lies an intriguing sector: the foot detox patch factory. These facilities are where ancient Eastern healing concepts converge with modern manufacturing techniques to produce a product that has captured the imagination of health-conscious consumers worldwide.

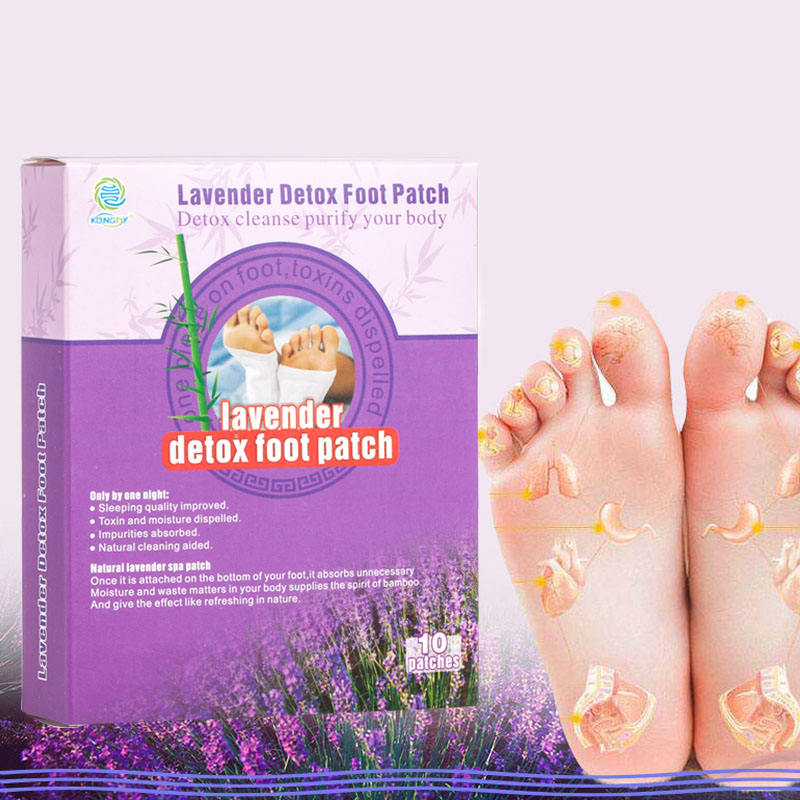

The production process in a foot detox patch factory is a blend of traditional knowledge and cutting-edge technology. It begins with the careful selection of raw materials. Ingredients like wood vinegar, bamboo charcoal, and various herbs are sourced from trusted suppliers who must meet stringent quality standards. These components are chosen for their purported ability to draw out toxins and impurities from the body.

Once the materials arrive at the factory, they undergo rigorous testing to ensure purity and potency. State-of-the-art laboratory equipment is used to analyze the chemical composition of each ingredient, ensuring consistency across batches. This step is crucial in maintaining the quality and efficacy of the final product.

The heart of the manufacturing process lies in the mixing and preparation of the active compounds. Skilled technicians, often with backgrounds in chemistry or traditional medicine, oversee this delicate process. The ingredients are combined in precise ratios, following formulas that may have been developed through years of research and refinement.

Advanced mixing equipment ensures that the ingredients are thoroughly blended, creating a homogeneous mixture that will form the core of the detox patch. This mixture is then applied to a specially designed adhesive pad, which allows for easy application to the foot while also facilitating the transfer of the active ingredients to the skin.

Quality control is a paramount concern in foot detox patch factories. Each batch of patches undergoes multiple inspections throughout the production process. This includes visual checks, adhesive strength tests, and analysis of the active compound distribution. Many factories also conduct stability testing to ensure the patches remain effective throughout their shelf life.

Packaging is another critical aspect of production. The patches must be sealed in airtight containers to preserve their potency and prevent contamination. Many factories use advanced packaging technologies, such as nitrogen flushing, to extend the product's shelf life and maintain its efficacy.

As the wellness industry evolves, so too do foot detox patch factories. Many are investing in research and development to improve their products and explore new formulations. Some factories are also embracing sustainable practices, using eco-friendly materials and implementing energy-efficient manufacturing processes.

The foot detox patch factory stands as a testament to the enduring appeal of traditional wellness concepts in the modern world. By combining ancient wisdom with contemporary manufacturing techniques, these facilities continue to produce products that resonate with consumers seeking alternative approaches to health and wellbeing.

0086 19937104978

0086 19937104978