Author:Kangdi 01-12-2023

Steam eye masks are an innovative health and wellness product that leverage the benefits of warm steam therapy to address issues like dry eye, puffiness, and sinus pressure. As these reusable masks grow increasingly popular worldwide, manufacturers must choose reliable suppliers able to deliver both quality and value across the production process. In this guide, we’ll analyze the pros and cons of utilizing overseas exporters versus domestic providers of essential steam eye mask components when embarking on manufacturing.

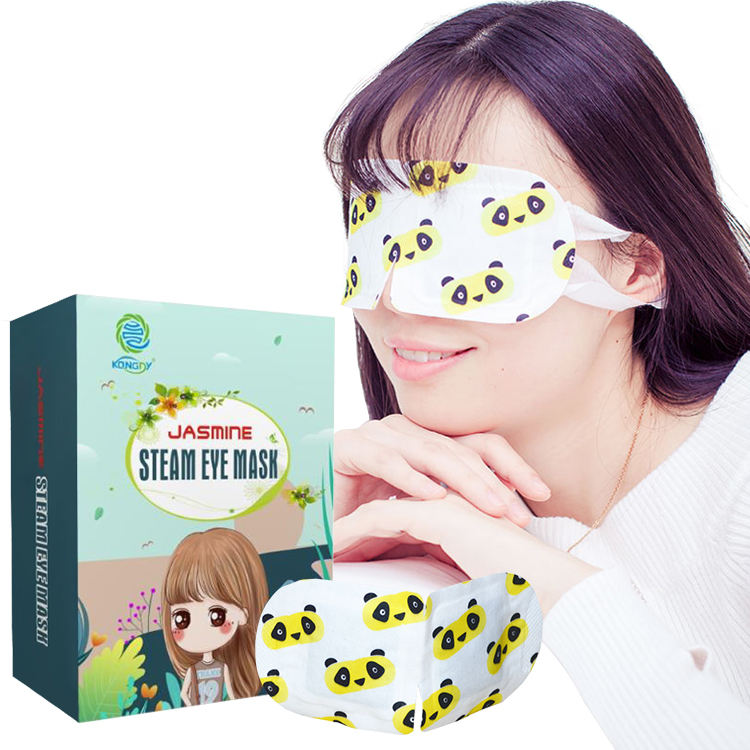

01. Key Steam Eye Mask Components

Steam eye masks consist of an insulated outer shell housing one or more heating pads, all incorporated into an adjustable, comfortably fitting eye mask shape. Manufacturers must source the following main components:

Outer Shell Fabric – Insulating synthetic or natural fabric often with soft inner lining

Heating Pads – Thin heat-generating packets with adhesive backing

Straps – Adjustable straps to ensure proper eye coverage area

Hardware – Lightweight plastic or metal parts like hinges and control units

Packaging – Retail packaging meeting safety and compliance standards

02. Overseas Supplier Considerations

Asia-based exporters offer the benefit of significant cost savings on most mask components. High volume manufacturers in countries like China and Taiwan can deliver essential parts at a fraction of the price of U.S.-based options. This ability to minimize expenditures is the primary advantage of overseas sourcing.

However, utilizing suppliers outside one’s home country also comes with potential downsides:

Language/Communication Issues – Misunderstandings arise more easily.

Long Lead Times – Production and shipping delays slow time-to-market.

Quality Control Challenges – Overcoming distant QA obstacles requires effort.

Time Zone Logistics – Coordinating with 12+ hour time differences is difficult.

Changing Regulations – Staying compliant with evolving laws demands vigilance.

03. Domestic Supplier Benefits

Alternatively, manufacturers can opt to collaborate with suppliers based in the same country as mask production facilities. Though initial component costs will likely be higher, domestic partners offer advantages around communication, adaptability, and speed:

Shared Language Eases Interactions – Discuss specifications, contracts and optimizations smoothly.

Faster Shipping Enables Flexibility – Make last-minute changes without long delays.

Advanced Technology & Capabilities – Leverage innovative production methods and materials.

Familiarity With Standards – Adherence to local regulations and protocols comes naturally.

Easier Partnership Building – Collaborate iteratively leveraging cultural intuitions.

By weighing variables like cost, compliance, responsiveness and more, manufacturers can determine the optimal supply chain configuration across geographies.

As demand for steam eye masks continues rising, manufacturers must choose manufacturing partners strategically to yield both product quality and profitability. This overview of offshoring vs. domestic sourcing tradeoffs provides key considerations when evaluating supply chain decisions. Please reach out with any other steam eye mask manufacturing questions!

0086 19937104978

0086 19937104978