Author:Kangdi 23-04-2023

Nose strips are adhesive strips that can be applied on the nose to improve breathing by opening up the nasal passages. These strips have become popular among people who struggle with snoring, allergies, or difficulty breathing. Many manufacturers offer OEM processing services to create customized nose strips for various brands.

01. Design and Customization

The first step in OEM processing is to work with the client to design and customize the nose strips according to their specific needs. The manufacturer will create a prototype based on the client's design and then make any necessary modifications until the client is satisfied with the design. This process ensures that the final product meets the client's exact specifications and needs.

02. Material Selection and Preparation

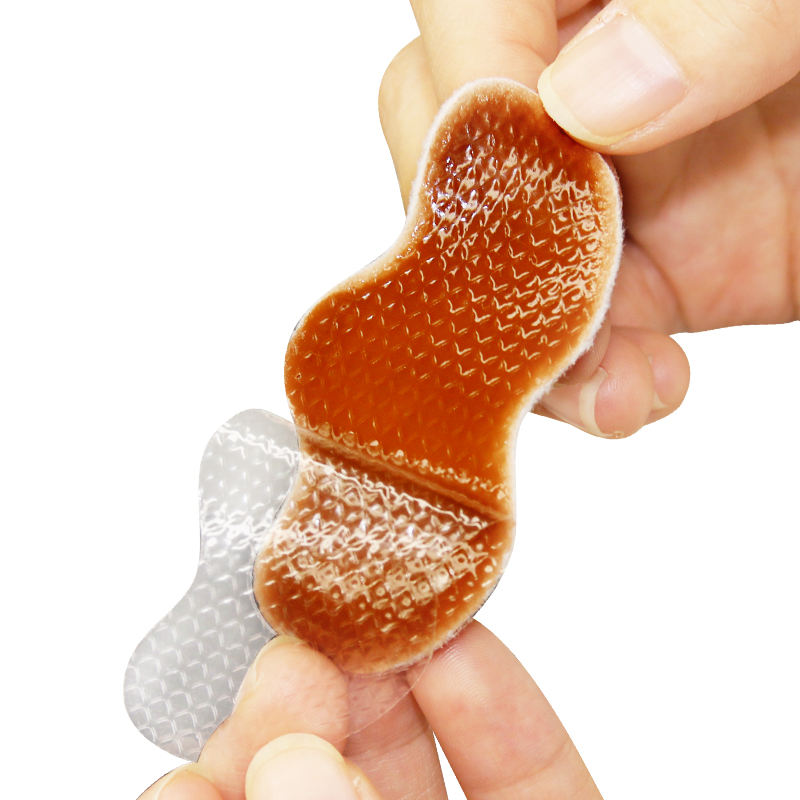

The next step is to select the appropriate materials for the nose strips. The manufacturer will work with the client to choose the right materials based on their desired level of stickiness, breathability, and comfort. Once the materials are selected, they will be prepared for production, which involves cutting them into the appropriate size and shape.

03. Production and Packaging

The actual production of the nose strips involves several steps. First, the adhesive is applied to the materials, followed by cutting the strips into the desired shape and size. After that, the strips are inspected to ensure that they meet the client's specifications. Finally, the strips are packaged and labeled for shipment to the client.

04. Quality Control and Assurance

The last step in the OEM processing of nose strips is quality control and assurance. The manufacturer will conduct quality checks at each stage of production to ensure that the nose strips meet the required standards. This involves checking the adhesive strength, size, shape, and overall quality of the finished product. Only after passing these quality checks will the nose strips be shipped to the client.

OEM processing of nose strips is a multi-step process that involves close collaboration between the manufacturer and the client. By working closely together, they can design and produce customized nose strips that meet the client's exact needs and specifications. The four processes outlined above are essential to ensure the production of high-quality nose strips that are comfortable, effective, and reliable.

0086 19937104978

0086 19937104978