Author:Kangdi 17-06-2024

The journey of premium capsicum from farm to pharmacy is a fascinating tale of agricultural expertise, advanced manufacturing, and innovative pain relief solutions. Capsicum, widely known for its active component capsaicin, has been celebrated for its medicinal properties, particularly in pain management. Our state-of-the-art plasters harness the power of this remarkable ingredient, offering effective and natural pain relief to countless individuals. This article explores the journey of capsicum from its cultivation to its transformation into top-quality pain relief plasters.

01. Processing and Extraction

Once harvested, the capsicum peppers are transported to our processing facilities. Here, the peppers undergo a meticulous cleaning and drying process to preserve their natural properties. The dried peppers are then subjected to an extraction process that isolates capsaicin, the key active ingredient responsible for pain relief.

Our state-of-the-art extraction methods ensure that the capsaicin retains its potency and purity. Advanced technology is used to achieve a high yield of capsaicin without compromising its natural effectiveness. The result is a premium-quality extract that forms the foundation of our pain relief plasters.

02. Manufacturing State-of-the-Art Plasters

The next step in the journey is the production of our state-of-the-art plasters. In our cutting-edge manufacturing facilities, the capsaicin extract is carefully integrated into the plaster formulation. Our team of experts ensures that the concentration of capsaicin is consistent across each plaster, guaranteeing reliable pain relief for our customers.

The manufacturing process involves several quality control checks to ensure that each plaster meets our high standards. The plasters are designed to provide controlled release of capsaicin, allowing for sustained pain relief over several hours. The adhesive used in our plasters is hypoallergenic and skin-friendly, ensuring comfort and minimizing the risk of irritation.

03. Packaging and Distribution

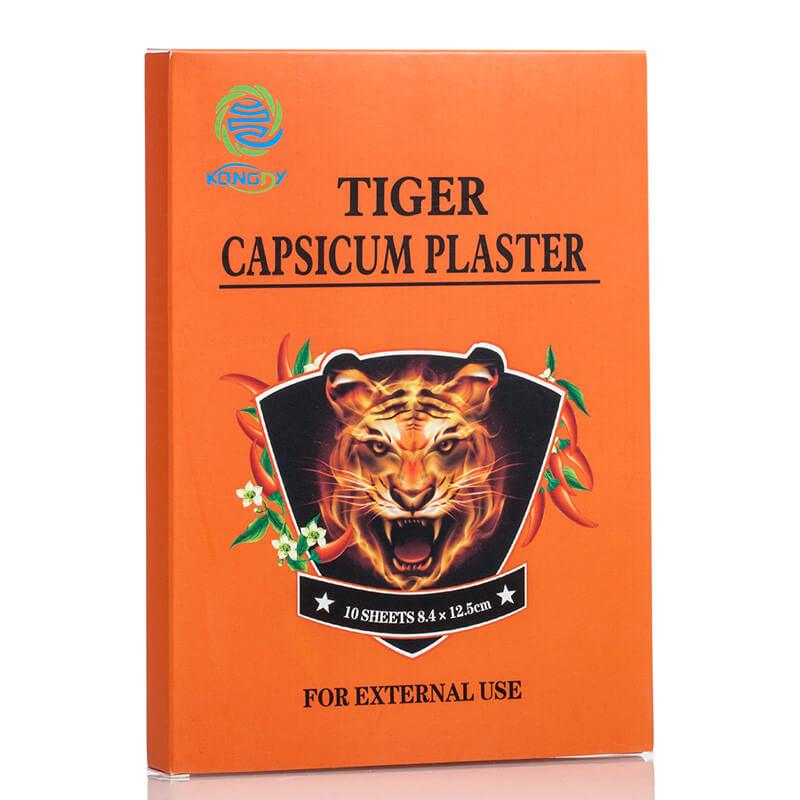

Once manufactured, the plasters are packaged in hygienic and tamper-proof packaging to maintain their integrity. Each package is labeled with detailed information, including usage instructions, ingredients, and safety warnings. Our packaging is designed to be user-friendly, allowing customers to easily access and apply the plasters.

From our manufacturing facilities, the plasters are distributed to pharmacies and retailers. Our efficient logistics network ensures that the plasters reach their destinations promptly, maintaining their freshness and effectiveness. We work closely with our distribution partners to ensure that our plasters are available to customers when and where they need them.

04. Real-World Impact

Our state-of-the-art capsicum plasters have made a significant impact on the lives of many individuals suffering from chronic pain. Capsaicin's ability to block pain signals and reduce inflammation provides effective relief for conditions such as arthritis, muscle pain, and nerve pain. Customers have reported significant improvements in their mobility and overall quality of life, thanks to the natural pain relief offered by our plasters.

The journey of premium capsicum from farm to pharmacy is a testament to the dedication and expertise involved in creating effective pain relief solutions. From sustainable farming practices and advanced extraction methods to meticulous manufacturing and efficient distribution, every step in the process is designed to ensure the highest quality product. Our state-of-the-art capsicum plasters provide natural, effective, and convenient pain relief, enhancing the well-being of countless individuals. By choosing our plasters, customers can trust that they are receiving a product that is the result of a rigorous and carefully managed journey from farm to pharmacy.

0086 19937104978

0086 19937104978