Author:Kangdi 19-11-2024

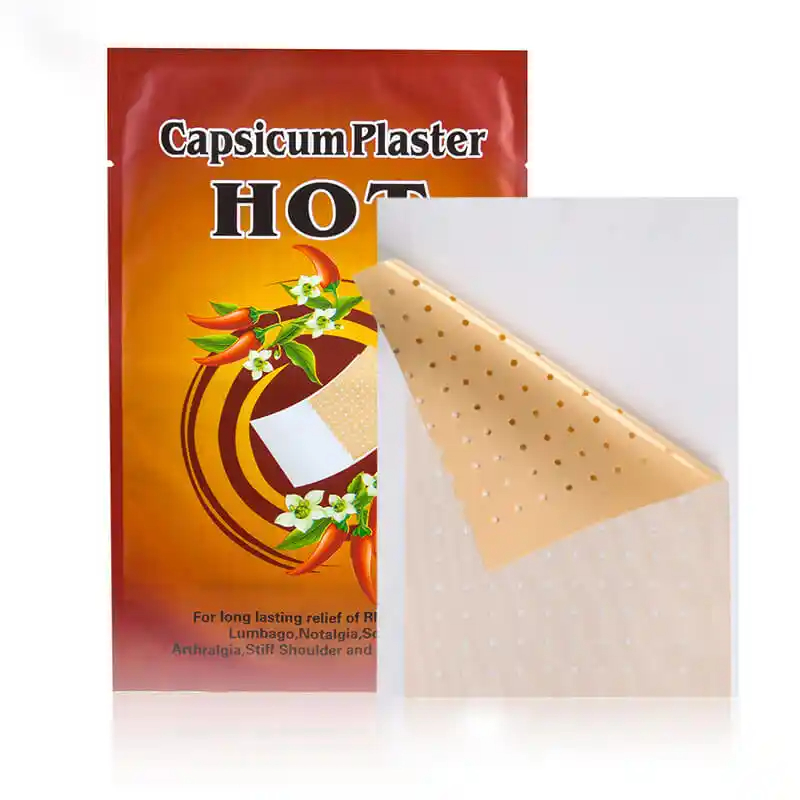

Capsicum plasters represent a fascinating blend of traditional medicine and modern pharmaceutical manufacturing techniques. These therapeutic patches, which harness the natural pain-relieving properties of capsaicin derived from chili peppers, have become increasingly popular for managing various types of pain.

The manufacturing process begins with the careful extraction of capsaicin from selected capsicum varieties. Modern facilities employ sophisticated extraction methods that ensure consistent potency and purity of the active compound. The extracted capsaicin undergoes rigorous testing to verify its concentration and quality before being incorporated into the plaster matrix.

The plaster base typically consists of several layers, each serving a specific purpose. The backing layer provides structural support and prevents the medication from transferring to clothing. The matrix layer contains the carefully formulated blend of capsaicin and other therapeutic ingredients, while the adhesive layer ensures proper skin contact for optimal drug delivery.

Quality control measures are implemented at every stage of production. Advanced spectroscopy techniques verify the uniform distribution of capsaicin throughout the matrix. Each batch undergoes stability testing to ensure the product maintains its efficacy throughout its shelf life. The manufacturing environment is strictly controlled for temperature and humidity to prevent any degradation of the active ingredients.

Modern capsicum plasters often incorporate additional pain-relieving compounds that work synergistically with capsaicin. These may include natural anti-inflammatory agents and circulation-promoting ingredients. The combination is carefully balanced to maximize therapeutic benefits while minimizing potential skin irritation.

The finishing process involves precision cutting equipment that ensures each plaster meets exact size specifications. Automated packaging systems seal each plaster in moisture-proof packets to preserve their effectiveness. Every package receives a unique tracking code for quality assurance and regulatory compliance.

Recent innovations in capsicum plaster technology include development of time-release formulations and improved adhesive systems that enhance wear comfort. Manufacturers continue to research new delivery methods to optimize the balance between therapeutic effectiveness and user comfort, making these traditional remedies increasingly relevant in modern pain management.

0086 19937104978

0086 19937104978